Gas fused quartz material

Suitable for semiconductor, photovoltaic and other industrial applications.

The company adopts high quality natural quartz sand, based on the independent process of manufacturing electrofused quartz ingots, can meet the semiconductor, photovoltaic, industrial and other industries on the stringent requirements of the quartz material, to provide customers with excellent material performance, stable, customizable large-size quartz materials and products.

Product Introduction

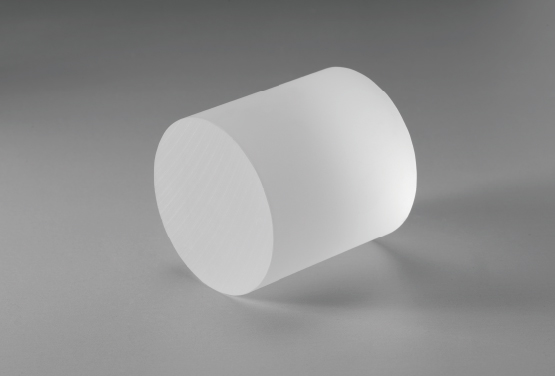

Our synthetic quartz glass ingots have excellent overall properties, low thermal conductivity, excellent resistance to thermal vibration, high deflection and softening temperatures, low thermal conductivity, low dielectric losses and optical transmission in the UV spectrum.

-

石英圆锭en

Model

AU0511en

Application Area

领域(英文)领域(英文)

Typical Dimensions (mm)

300*500en

Product Features

特点(英文)特点(英文)特点(英文)

Product Advantages

After more than 20 years of technological research and process exploration, the company's melting quartz technology has reached a leading position in China, with most product indicators reaching international advanced levels. In particular, the optical non-uniformity index of UV optical quartz glass is the first in the industry in China to achieve a level within 2 (1.985×10^-6), and the non-uniformity index stability of existing products can be maintained within 4.

a. The company pioneered the vertical single-lamp integrated deposition system, which integrates raw material pretreatment, reaction synthesis, and quartz growth modules.

b. Super-precise combustion control and liquid evaporation create a constant flow field to ensure high purity.

c. Excellent matching between the combustion chamber’s thermal field and the advanced deposition furnace's temperature field creates optimal synthesis interfaces and product cross-sections.

d. Advanced automation control enables consistent axial growth and axial symmetry.

e. Defect distribution after lateral extension is suppressed, and secondary defects are improved through precise trough thermal shaping.

f. Independent development of multi-stage precision annealing process reduces the impact of stress.

-

High softening temperature and high heat resistanc

-

Pure high corrosion resistance

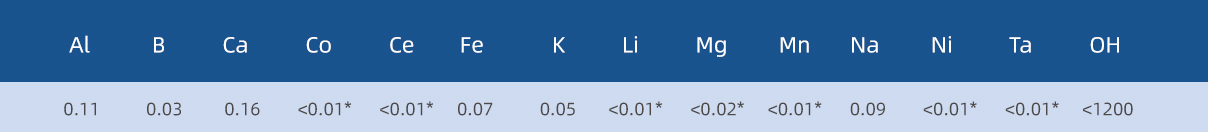

Performance Parameter

Impurity Content(ppm)

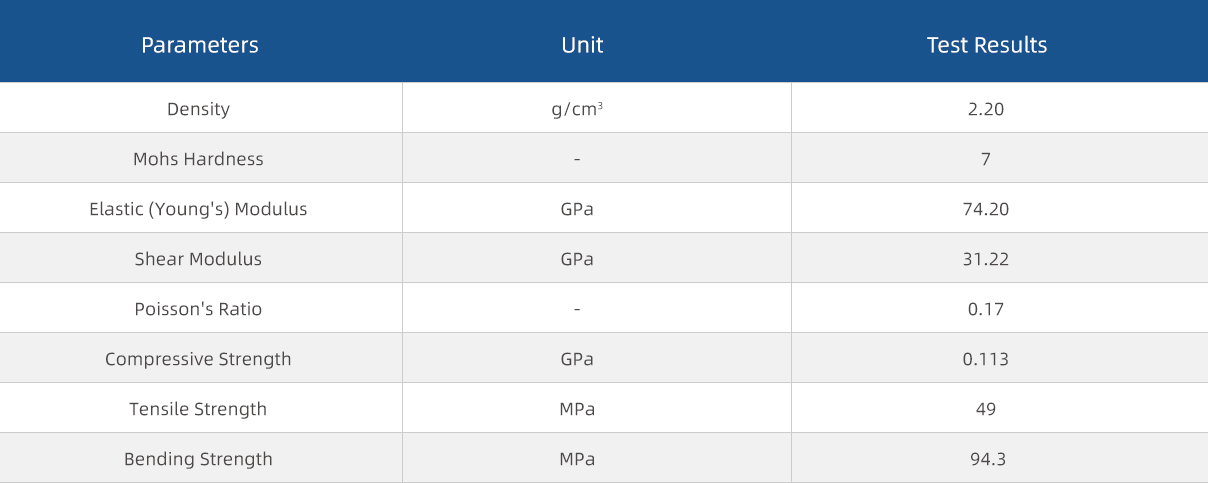

Mechanical Property

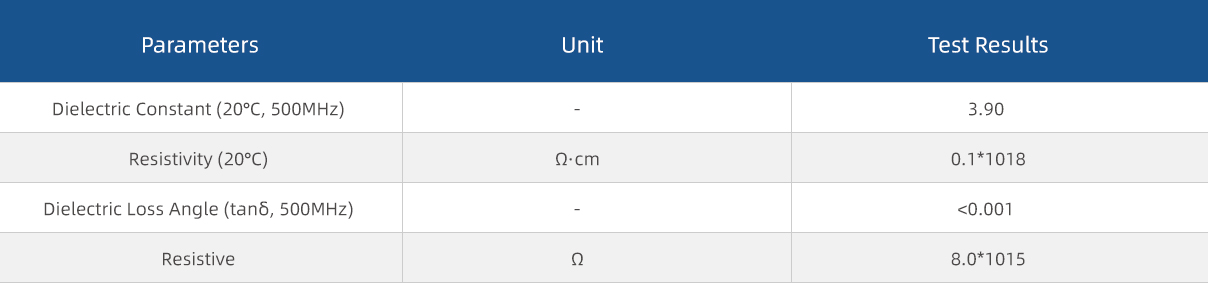

Electrical Properties

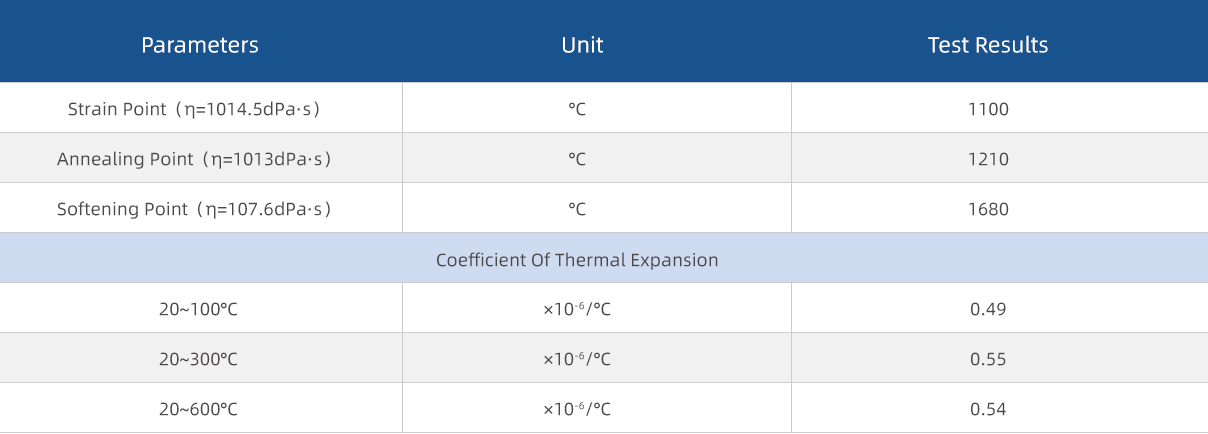

Thermal Properties

Contact Information For More Information

-

More contact information

Our experts are here to help find the optimal materials for your application

>Contact Us -

Customization Zone

Custom Product Size and Style

-

Placing an Order for Product Information

Purchasing Desired Product